Alur Aluminum is located in the industrial area of Grundartangi. Alur was established in Helguvík in 1998 and has operated at Grundartangi since 2012. Our main activity is dross processing, annual production ammounts about 3.600 tonnes of aluminium from 7 thousand tonnes of aluminum dross. The company has an operating licence to receive 15.000 tonnes of aluminum dross each year until 2025.

Our focus has been on optimizing the processes and maximizing the recovery of aluminum and thus reducing the environmental impact. Recoveries have never been greater, this has reduced the formation of saltslag and other waste materials that occur during the recycling of aluminum dross.

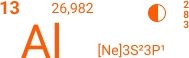

Aluminum

can be recycled

indefinitely

Near 75% of all aluminium ever made is still in use

It requires up to 95% less energy to recycle aluminium than to produce primary metal

Aluminium is the third most common element in the earth's crust – only oxygen and silicon exist in greater amounts

Recycling 1T of aluminium saves 9T of CO2 emissions and 4T of bauxite – the raw material from which aluminium is made.

Aluminum recycling reduces greenhouse gas emissions.

Aluminium is unique in that it can be used again and again without losing its original properties. Only about 5% of the energy originally used to produce the aluminium is needed to recycle it.

This means that much value is generated when the aluminium is recycled, which provides the foundation for the operation of recycling companies all over Europe.

Energy savings due to aluminum recycling significantly reduce greenhouse gas emissions, as the majority of emissions in global aluminium production is generally due to energy production.

#recyclethealuminium

More

Our goal is to optimize our process and close the loop at Grundartangi by sorting and recycling everything on site.